MSP 107

The re-engineered MSP 107 is back, bringing a new level of precision to its award-winning all-terrain dominance. Honored as 'Best Of' by Outside and Ski Magazine for two seasons running, the 107 is built to excel in soft, chopped, and variable snow without sacrificing groomer performance.

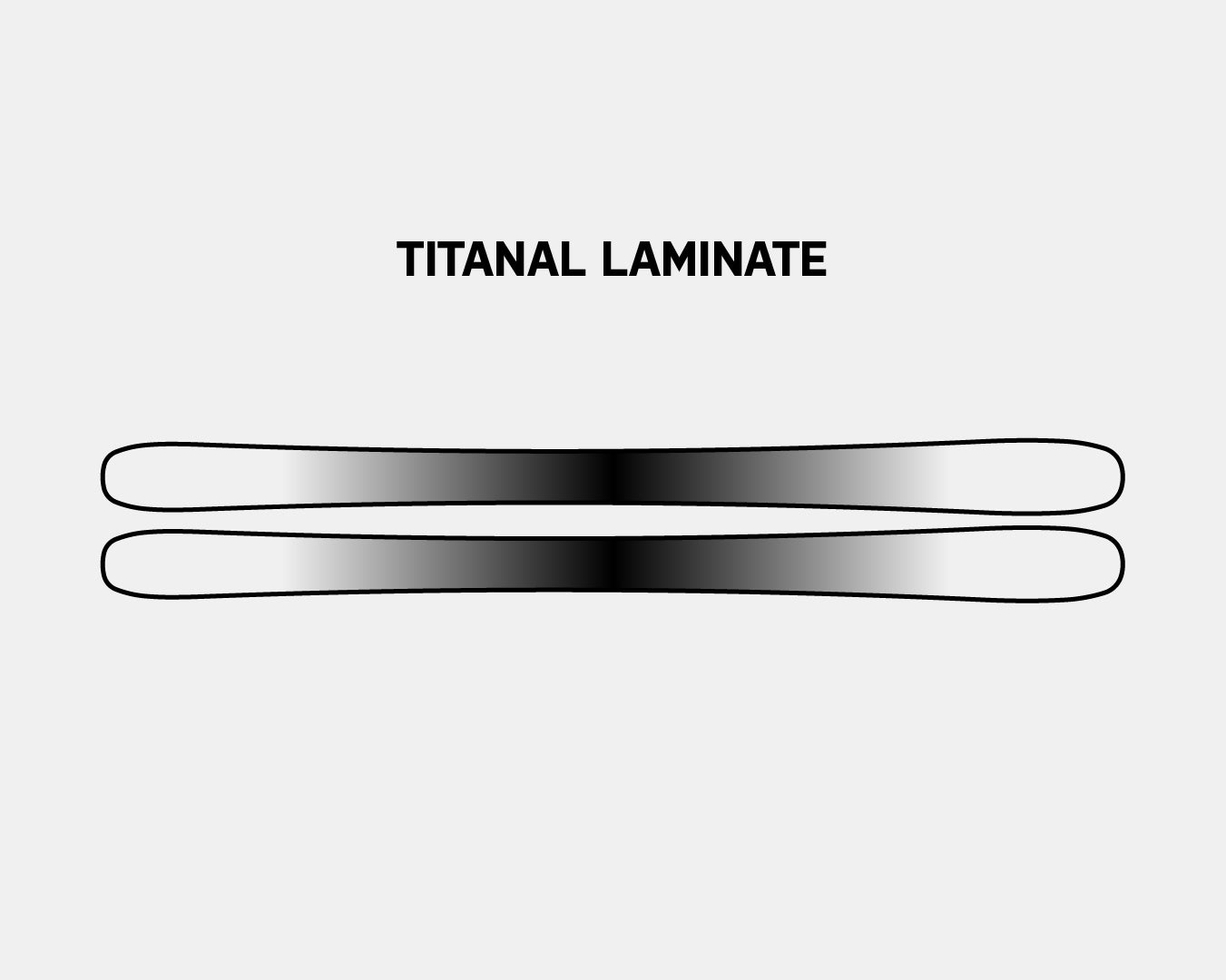

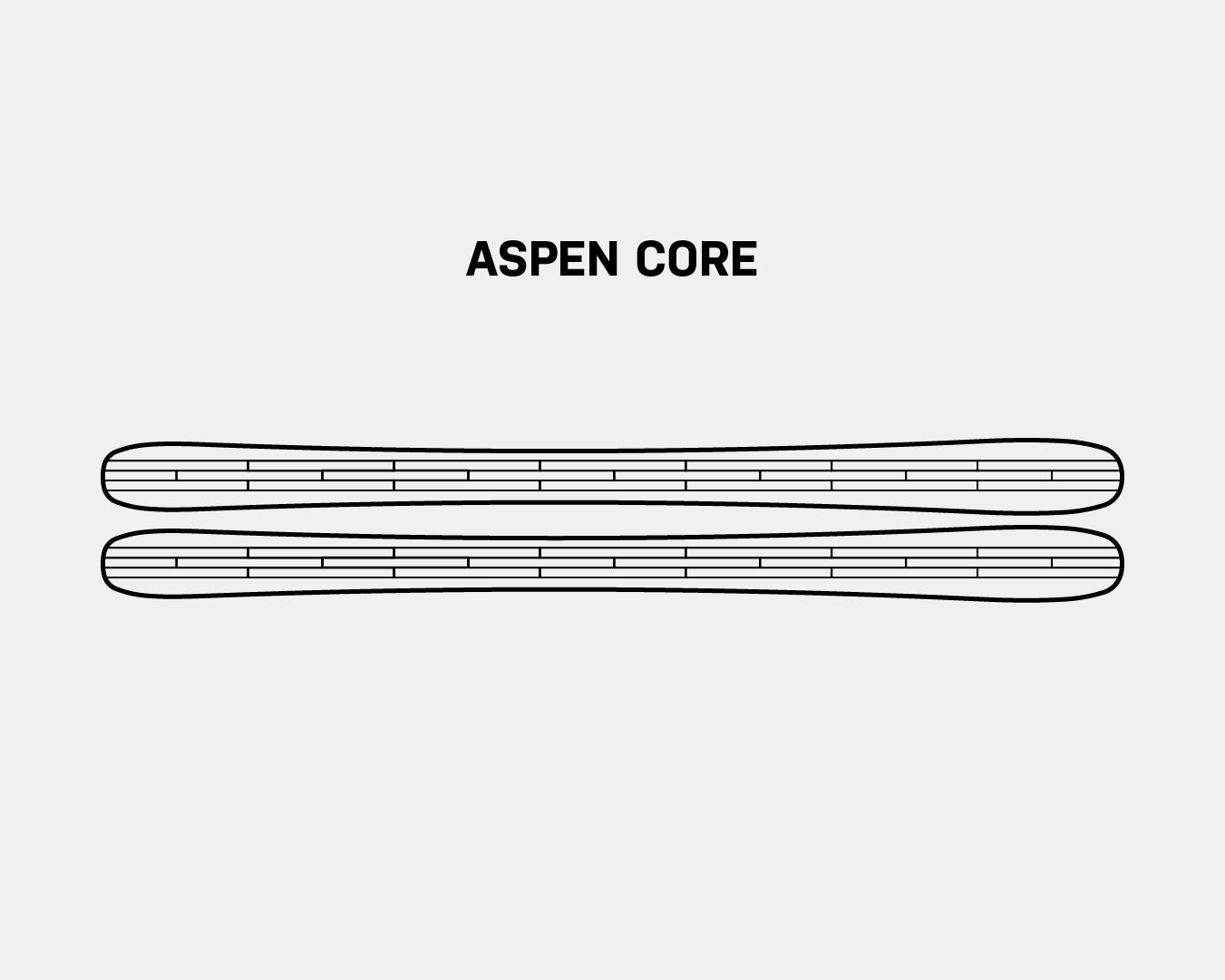

An Aspen/Maple core paired with a Titanal laminate delivers explosive energy, powerful edge grip, and rock-solid stability, whether you’re carving high speed arcs, threading steep trees, or slashing pow stashes. With its confidence inspiring feel and nimble, responsive handling, the MSP 107 is your ticket to charging harder and skiing stronger across every inch of the resort.

Art By Skyline Printworks

If for any reason you are not 100% satisfied with any of our products after your first 5 days of using, wearing, or skiing them, you can send them back for an exchange or a 100% refund of the total product cost. Learn more here.

4FRNT is committed to making the highest quality products from the highest quality materials. Therefore, we stand by our products with confidence and back them all with a 3-year manufacturer warranty, protecting them from defects in materials and workmanship. Learn More here

Tech Features

Complete Specs

Select your ski length for a detailed breakdown of all specs

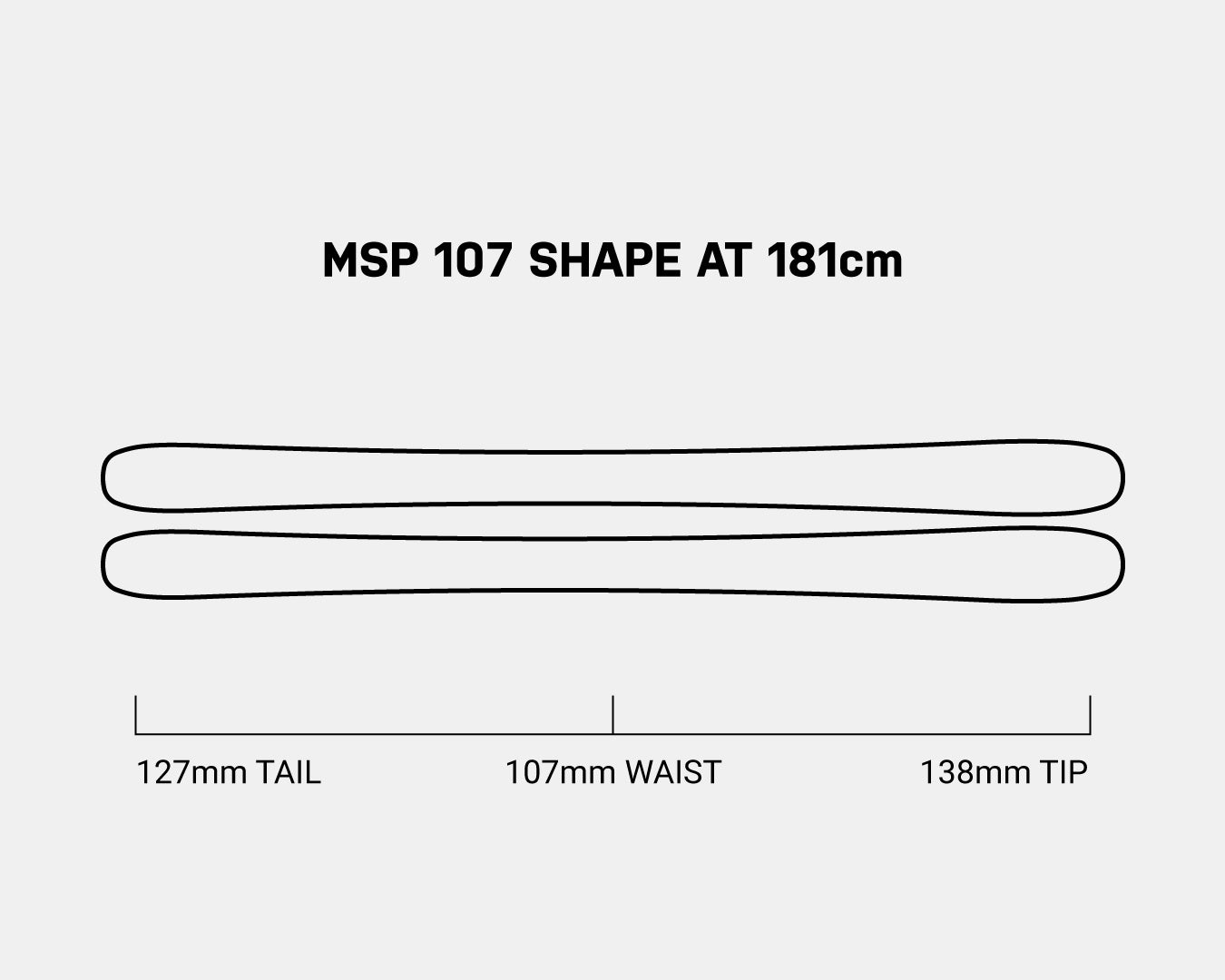

Dimensions: 137-107-126 mm

Weight: 2164 gr

Sidecut Radius: 18.5 m

Effective Edge: 1427 mm

Mount Point From Tail: 775 mm

Tip Height: 60 mm

Tail Height: 17 mm

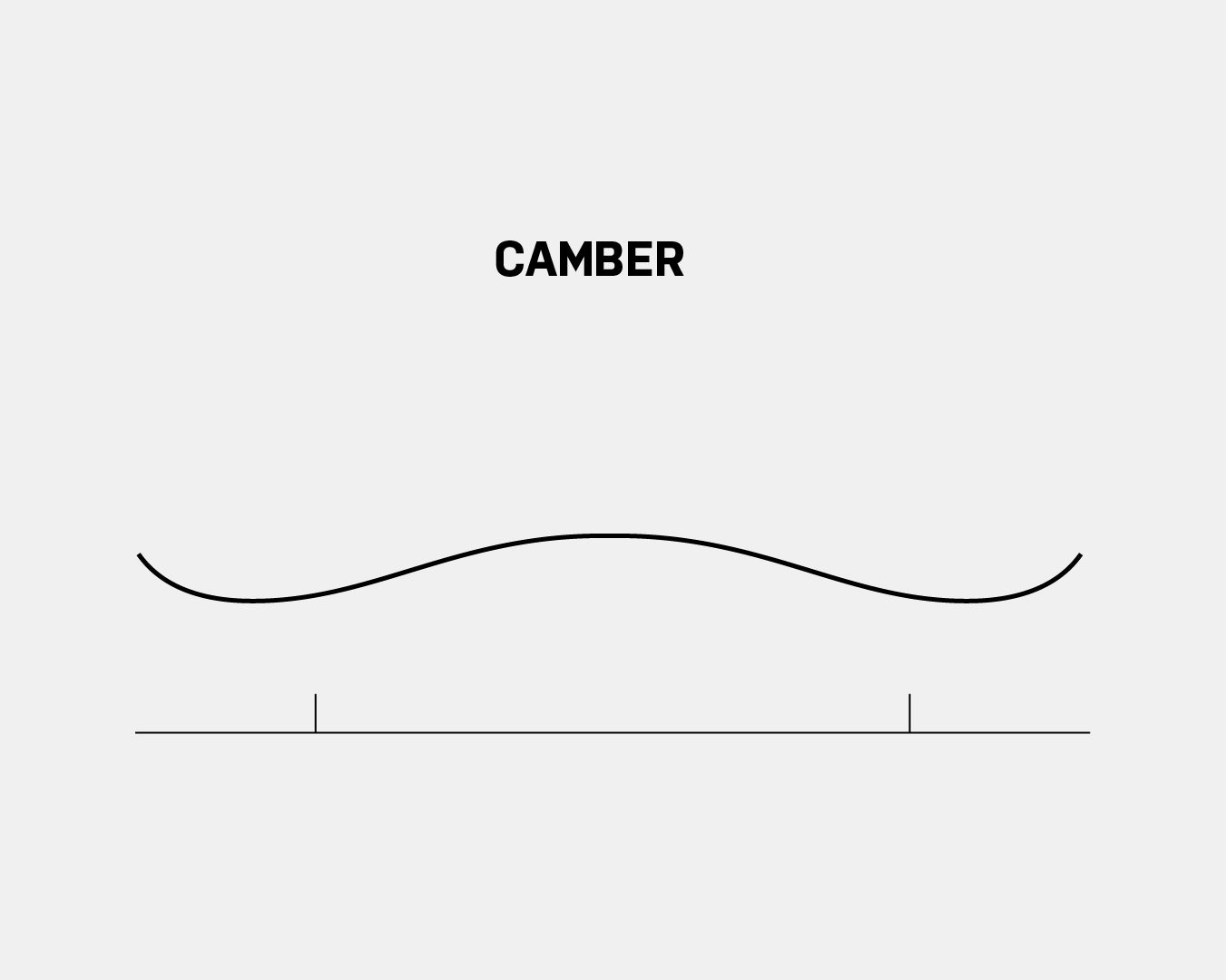

Camber: 5 mm

Dimensions: 137-107-126 mm

Weight: 2232 gr

Sidecut Radius: 19.5 m

Effective Edge: 1470 mm

Mount Point From Tail: 794 mm

Tip Height: 60 mm

Tail Height: 17 mm

Camber: 5 mm

Dimensions: 137-107-127 mm

Weight: 2311 gr

Sidecut Radius: 20 m

Effective Edge: 1510 mm

Mount Point From Tail: 818 mm

Tip Height: 60 mm

Tail Height: 17 mm

Camber: 5 mm

Dimensions: 137-107-128 mm

Weight: 2432 gr

Sidecut Radius: 20.75 m

Effective Edge: 1566 mm

Mount Point From Tail: 846 mm

Tip Height: 60 mm

Tail Height: 17 mm

Camber: 5 mm