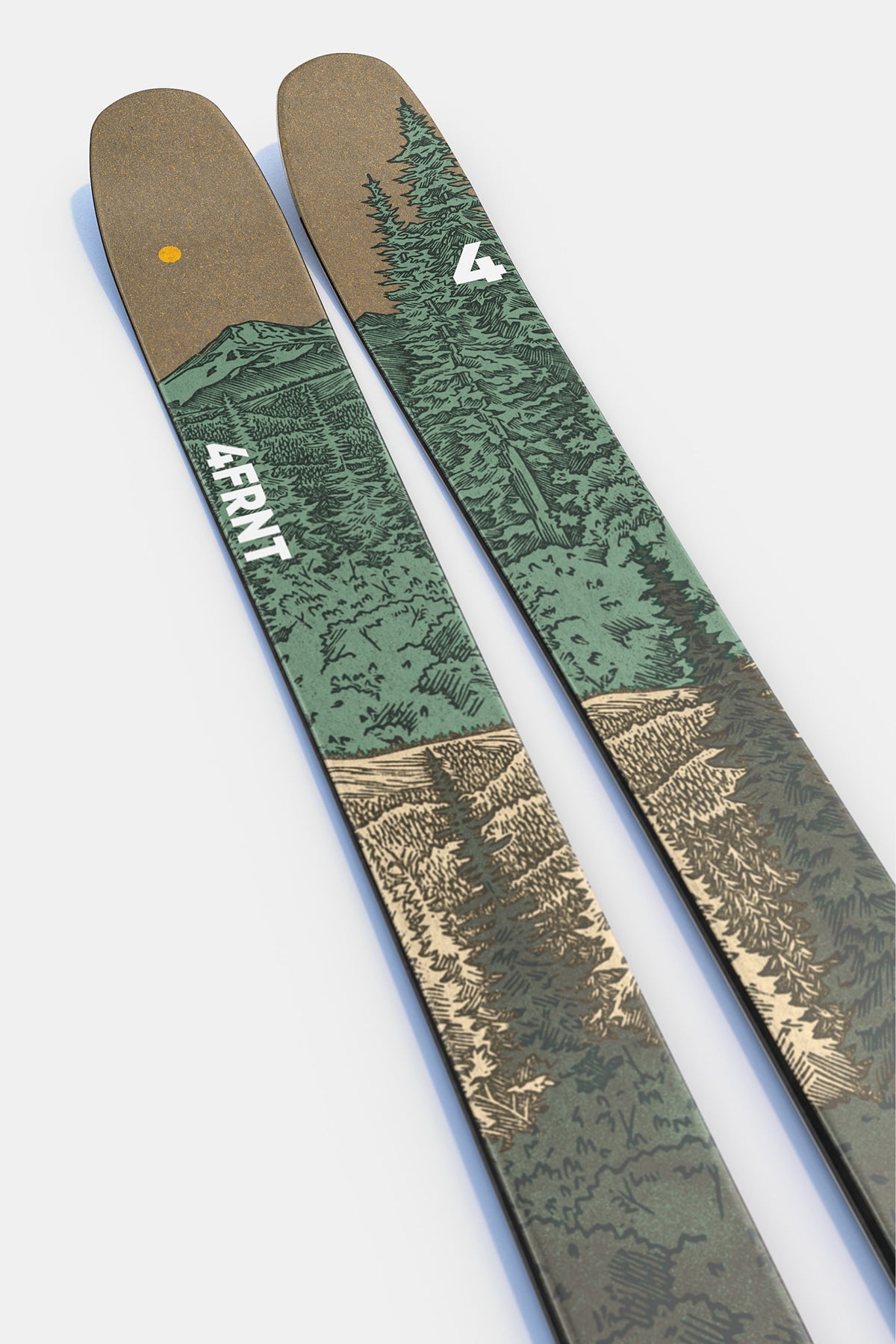

MSP 99

The MSP 99 returns as our most awarded ski, with top honors from Ski Magazine, Outside, and Blister cementing its status as the gold standard in the All-Mountain category. The refined core construction and precision tuned flex give the 99 quicker turn initiation, more rebound, and unmatched edge hold, making it even more capable from first chair to last lap.

Whether you’re carving corduroy, slicing through chop, or charging steeps, the MSP 99 delivers the perfect blend of stability, power, and agility. It’s the ski that pushes you to ski harder, smoother, and with more confidence every day.

Art by Skyline Printworks

If for any reason you are not 100% satisfied with any of our products after your first 5 days of using, wearing, or skiing them, you can send them back for an exchange or a 100% refund of the total product cost. Learn more here.

4FRNT is committed to making the highest quality products from the highest quality materials. Therefore, we stand by our products with confidence and back them all with a 3-year manufacturer warranty, protecting them from defects in materials and workmanship. Learn More here

Tech Features

Complete Specs

Select your ski length for a detailed breakdown of all specs

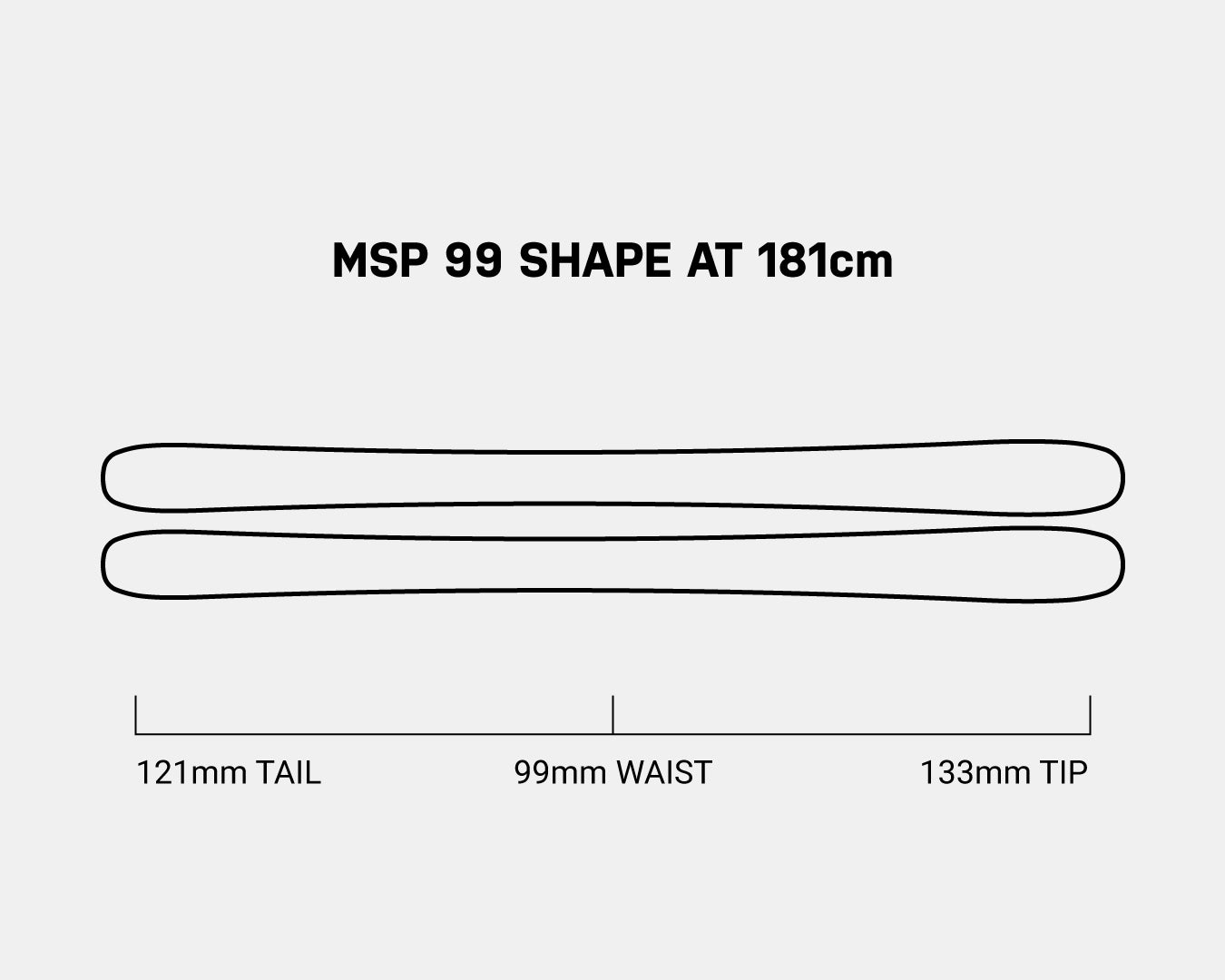

Dimensions: 133-99-121 mm

Weight: 2079 gr

Sidecut Radius: 16.75 m

Effective Edge: 1442 mm

Mount Point From Tail: 774 mm

Tip Height: 60 mm

Tail Height: 12 mm

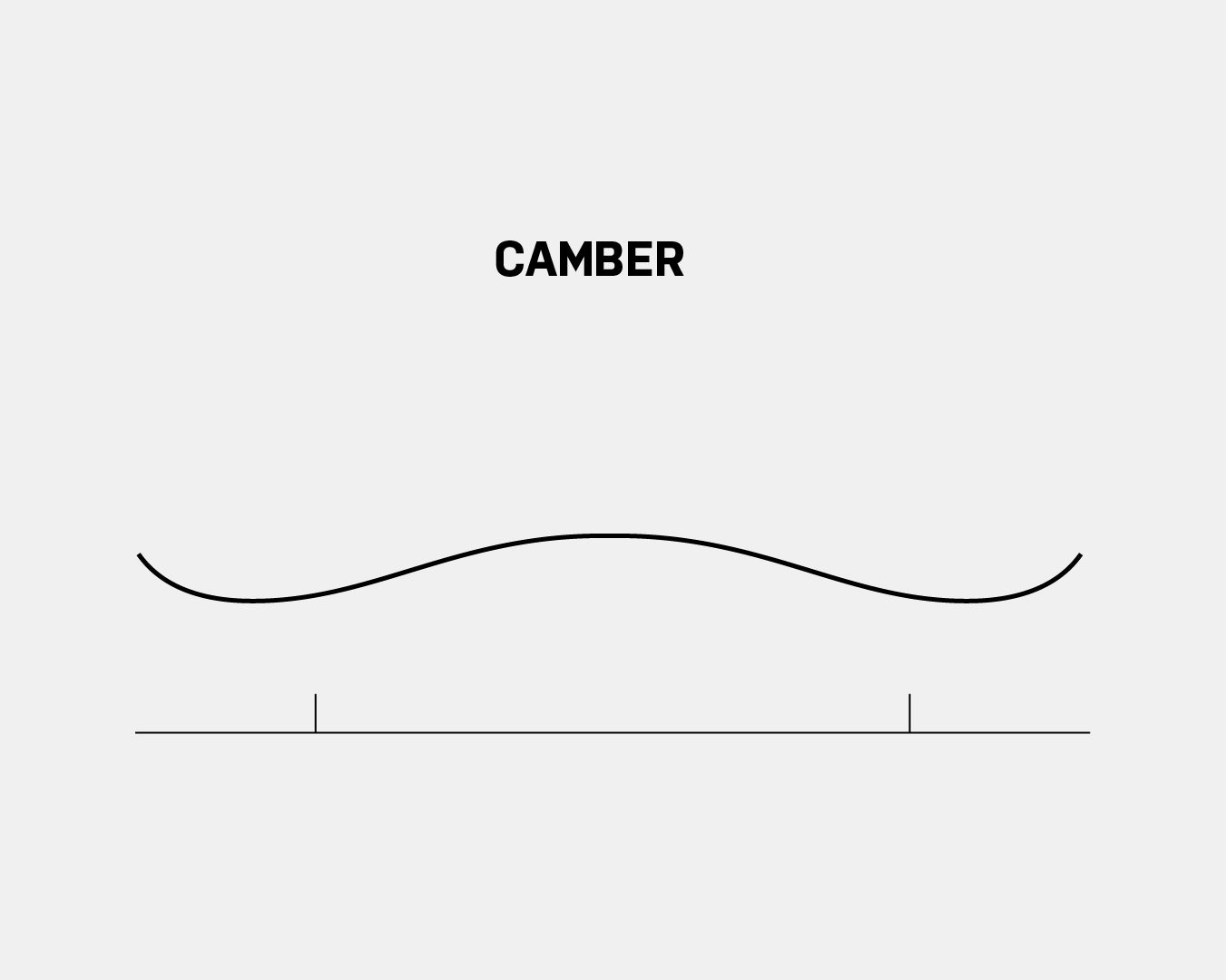

Camber: 5 mm

Dimensions: 133-99-121 mm

Weight: 2117 gr

Sidecut Radius: 17.5 m

Effective Edge: 1481 mm

Mount Point From Tail: 794 mm

Tip Height: 60 mm

Tail Height: 12 mm

Camber: 5 mm

Dimensions: 133-99-122 mm

Weight: 2200 gr

Sidecut Radius: 18 m

Effective Edge: 1522 mm

Mount Point From Tail: 817 mm

Tip Height: 60 mm

Tail Height: 12 mm

Camber: 5 mm

Dimensions: 133-99-122 mm

Weight: 2363 gr

Sidecut Radius: 19 m

Effective Edge: 1572 mm

Mount Point From Tail: 846 mm

Tip Height: 60 mm

Tail Height: 12 mm

Camber: 5 mm