HOJI

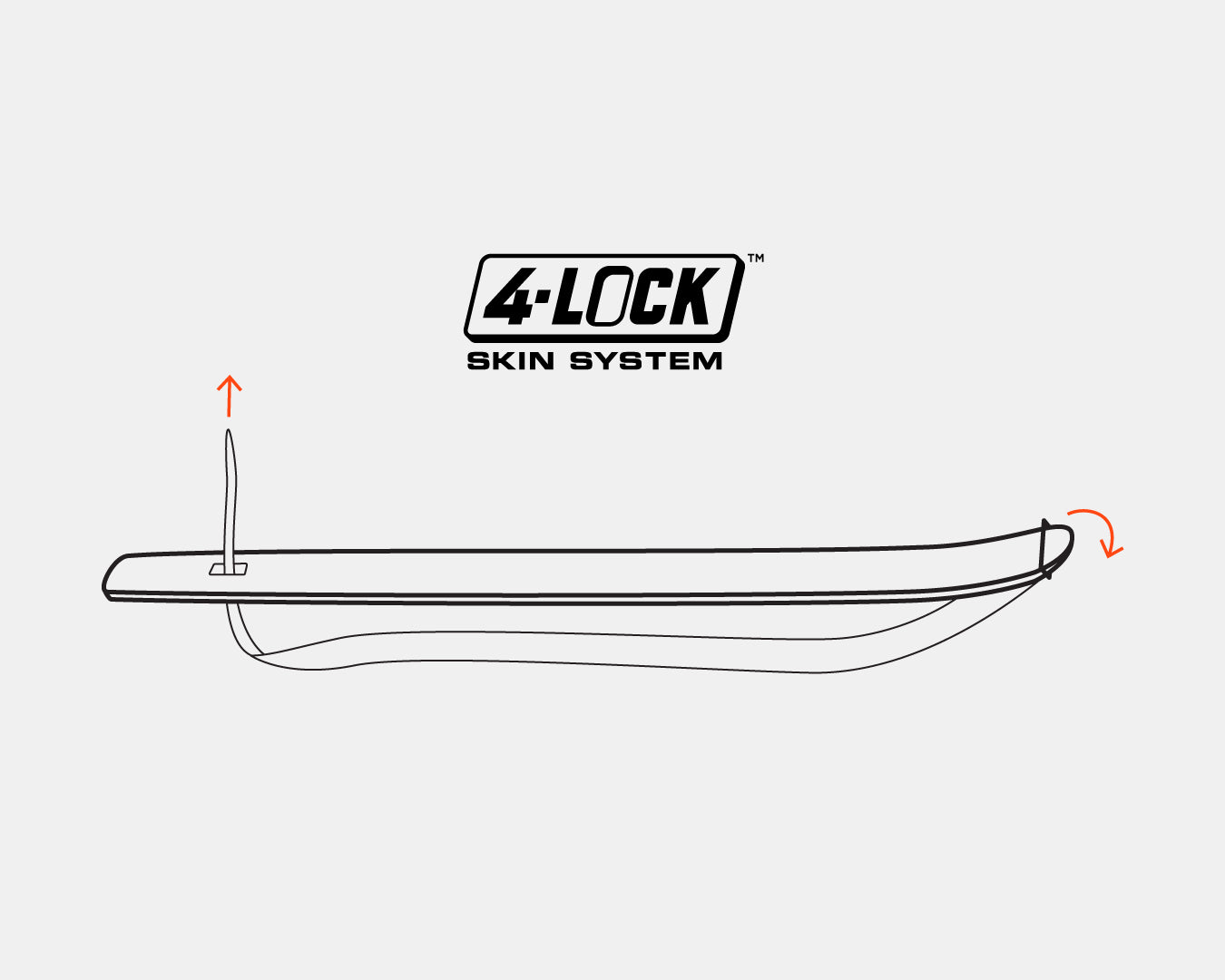

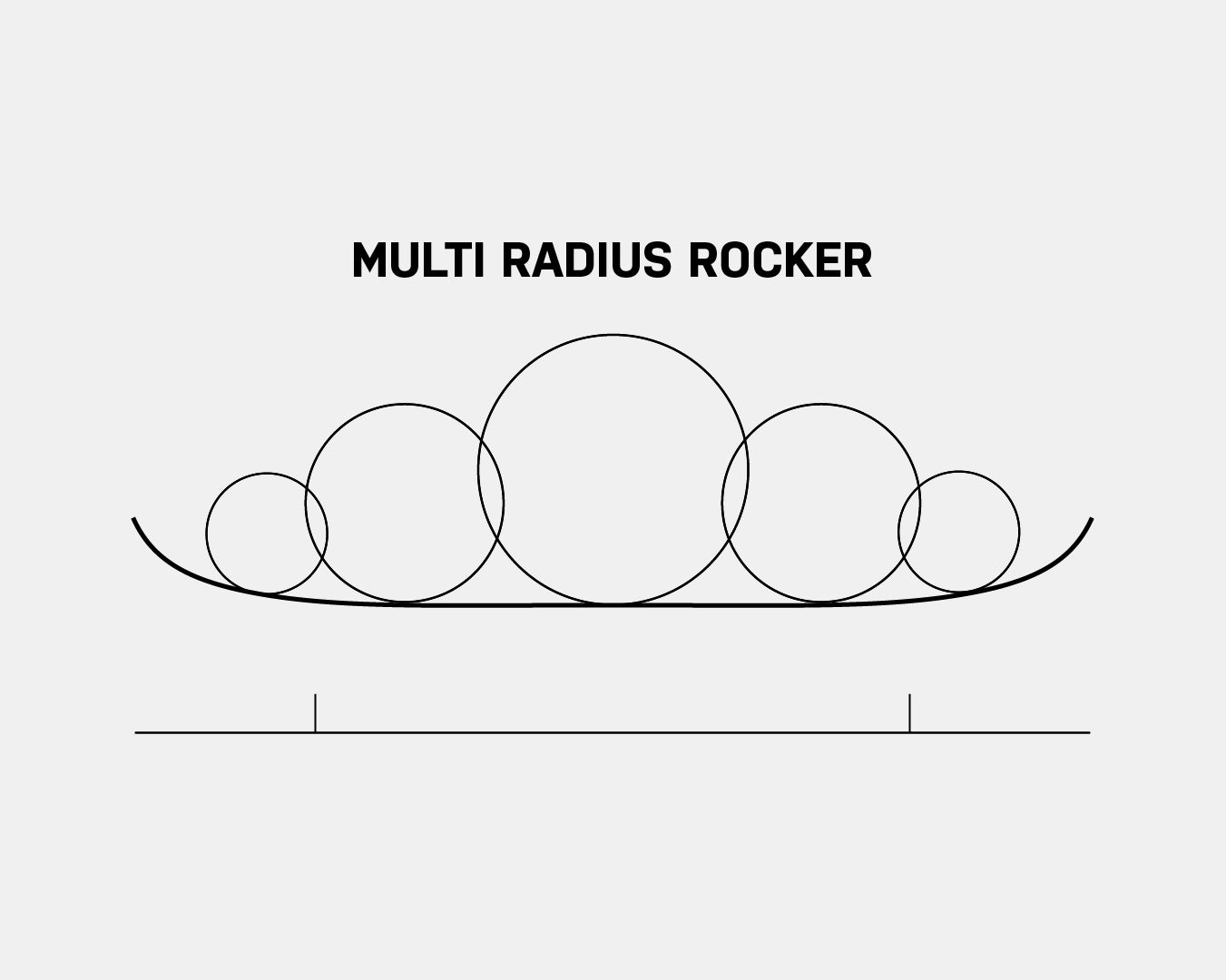

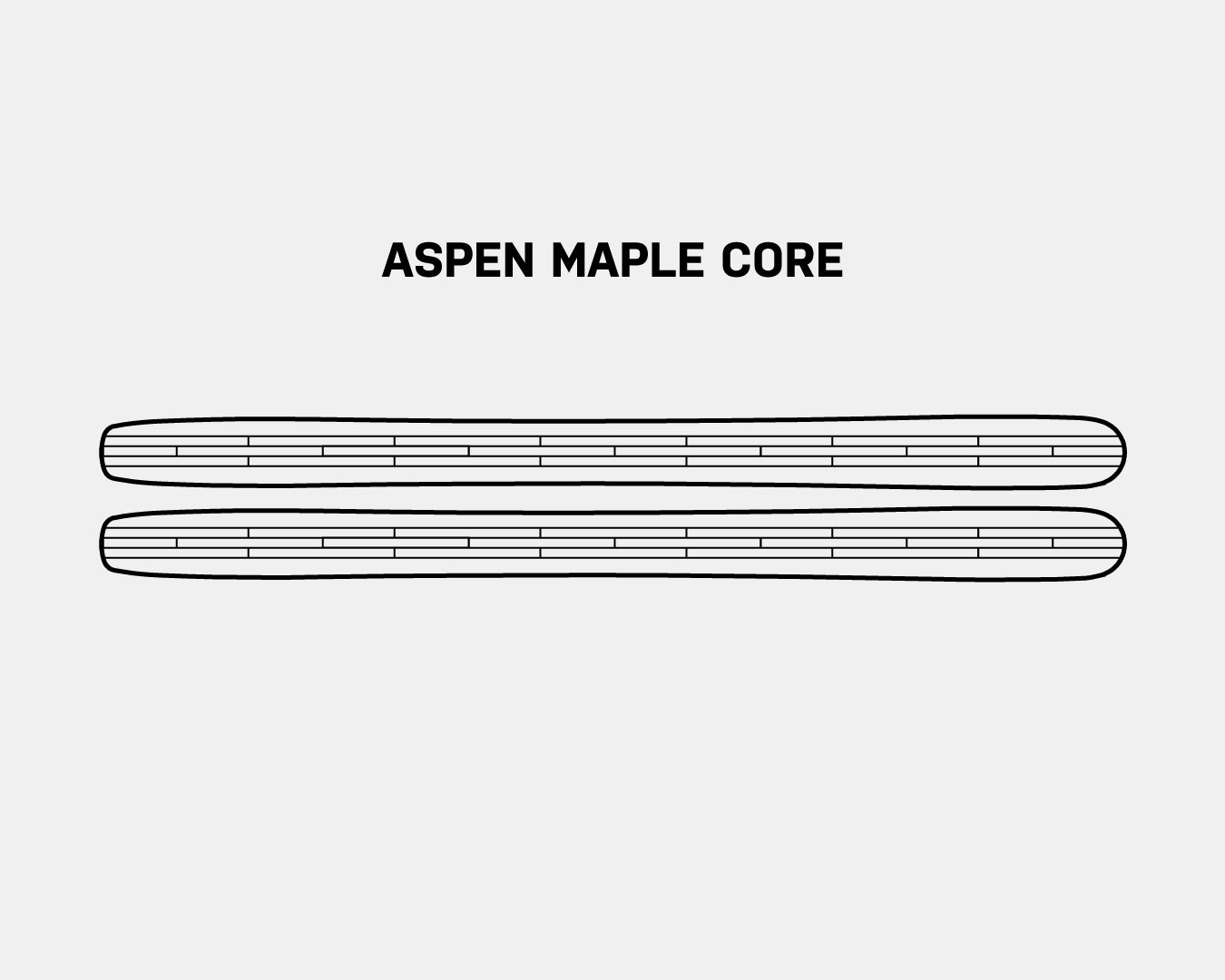

The Hoji continues to lead the charge with its legendary adaptability everywhere inbounds and out. Our signature Multi Radius Rocker provides an exceptional blend of soft snow flotation and firm snow control. The balance of the Aspen and Maple core creates more energy to pop, carve, and slash than anything you’ve skied before all while maintaining a weight that’s just as comfortable on the up as it is down. Whether you’re on the skin track, picking your way through technical chutes, or slashing deep turns around the resort, the Hoji will elevate your game!

This season we are stoked to offer the Hoji with an incredible graphic featuring art by See Machine.

If for any reason you are not 100% satisfied with any of our products after your first 5 days of using, wearing, or skiing them, you can send them back for an exchange or a 100% refund of the total product cost. Learn more here.

4FRNT is committed to making the highest quality products from the highest quality materials. Therefore, we stand by our products with confidence and back them all with a 3-year manufacturer warranty, protecting them from defects in materials and workmanship. Learn More here

Tech Features

Complete Specs

Select your ski length for a detailed breakdown of all specs

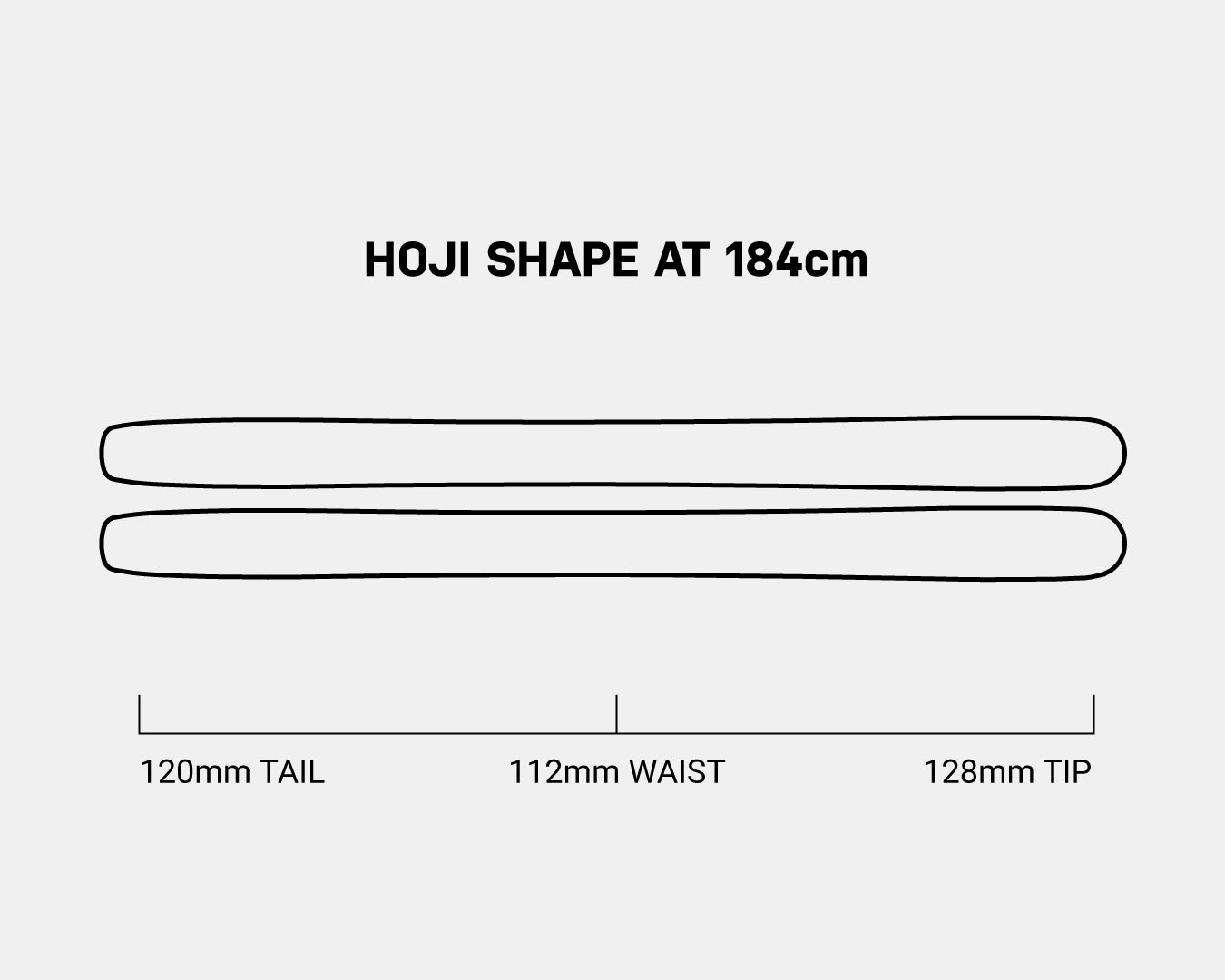

Dimensions: 128-112-120 mm

Weight: 1790 gr

Sidecut Radius: 30 m

Effective Edge: 1160 mm

Mount Point From Tail: 780 mm

Tip Height: 85 mm

Tail Height: 30 mm

Camber: Multi-Radius

Dimensions: 128-112-120 mm

Weight: 1888 gr

Sidecut Radius: 30 m

Effective Edge: 1230 mm

Mount Point From Tail: 815 mm

Tip Height: 88 mm

Tail Height: 33 mm

Camber: Multi-Radius

Dimensions: 128-112-120 mm

Weight: 1990 gr

Sidecut Radius: 30 m

Effective Edge: 1300 mm

Mount Point From Tail: 850 mm

Tip Height: 90mm

Tail Height: 35 mm

Camber: Multi-Radius

Dimensions: 128-112-120 mm

Weight: 2066 gr

Sidecut Radius: 30 m

Effective Edge: 1370 mm

Mount Point From Tail: 885 mm

Tip Height: 92 mm

Tail Height: 37 mm

Camber: Multi-Radius