Raven

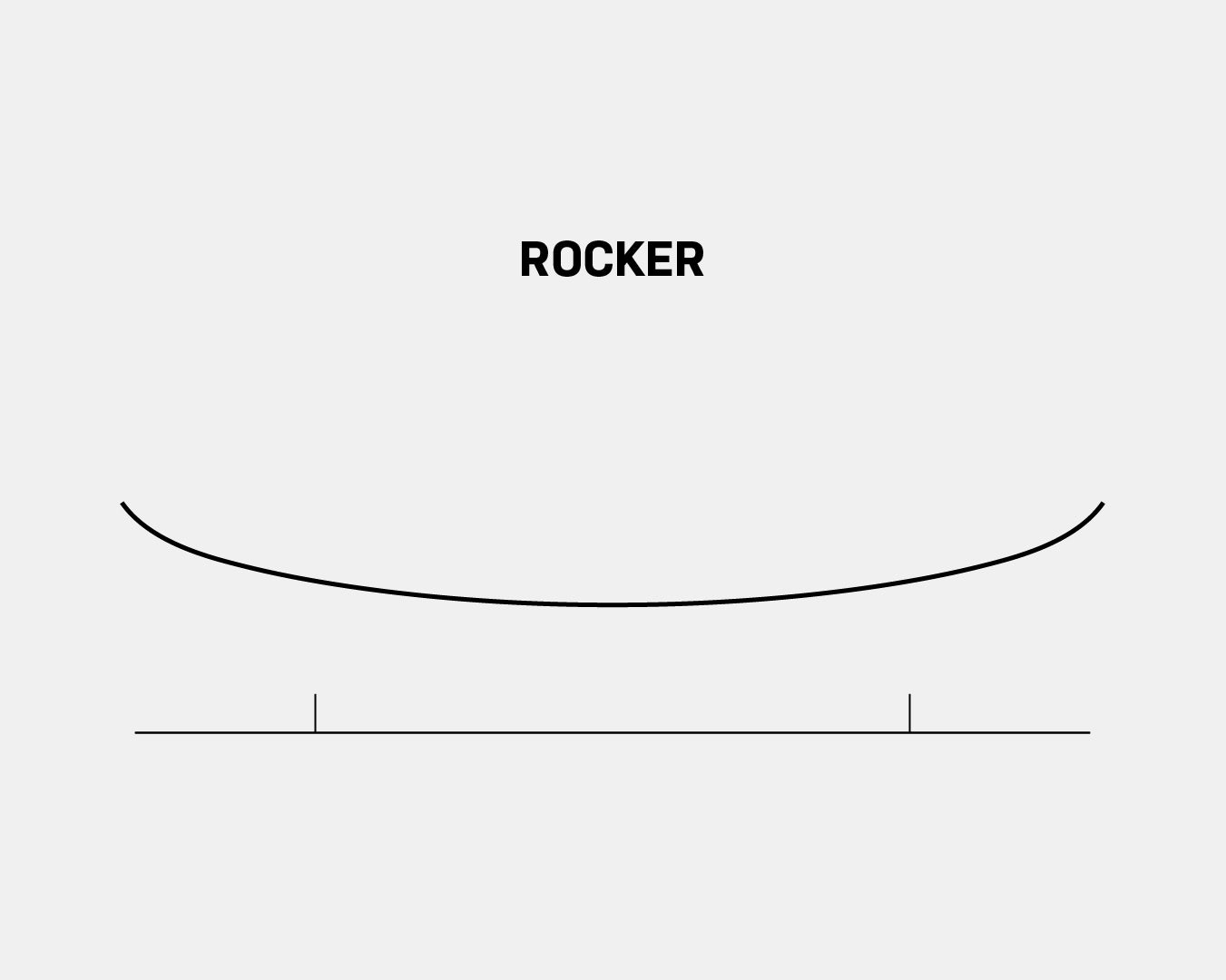

Engineered for skiers who earn turns, the Raven delivers unmatched uphill efficiency without compromising downhill performance. Its smooth, fully rockered shape naturally lifts your tips above fresh snow, making breaking trail effortless. On the descent, the Raven’s pre-bent rocker profile unlocks supreme maneuverability, responsive control, and smooth surfy turns, perfect for tight trees, steep chutes, and technical terrain.

If your ideal day starts long before the lifts spin and ends with untouched lines deep in the backcountry, the Raven is your ultimate tool for the mission.

Art by See Machine

If for any reason you are not 100% satisfied with any of our products after your first 5 days of using, wearing, or skiing them, you can send them back for an exchange or a 100% refund of the total product cost. Learn more here.

4FRNT is committed to making the highest quality products from the highest quality materials. Therefore, we stand by our products with confidence and back them all with a 3-year manufacturer warranty, protecting them from defects in materials and workmanship. Learn More here

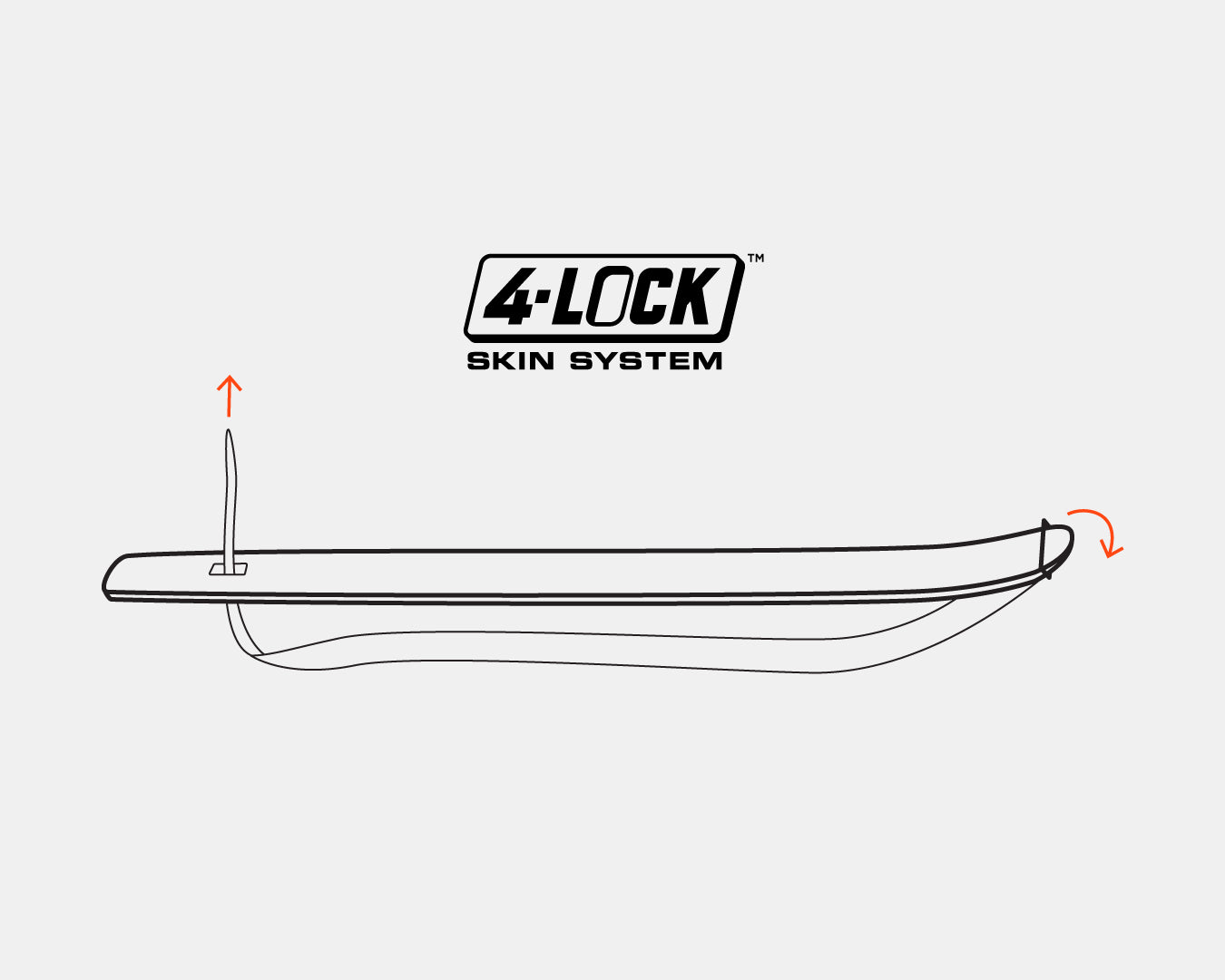

Tech Features

Complete Specs

Select your ski length for a detailed breakdown of all specs

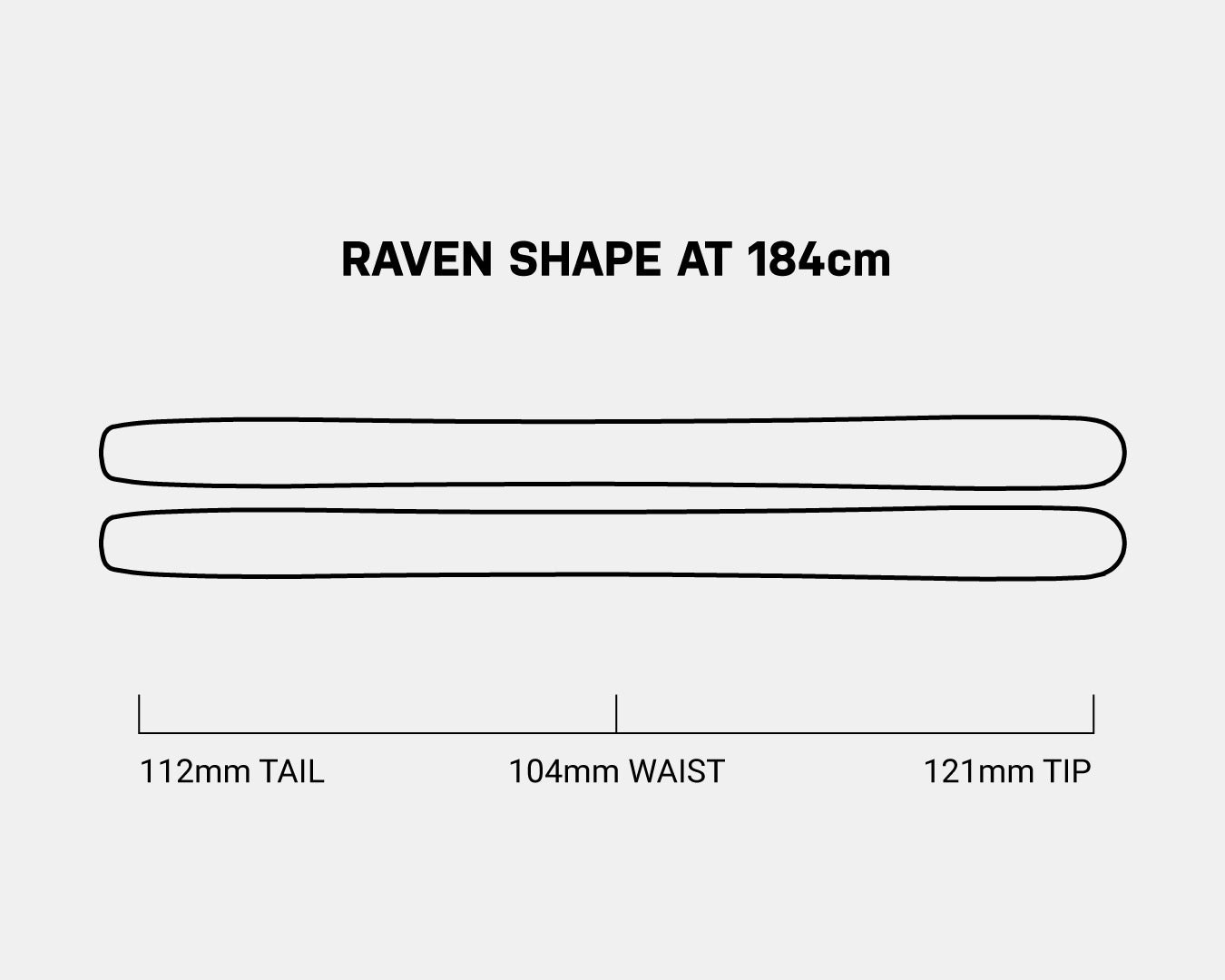

Dimensions: 120-104-111 mm

Weight: 1658 gr

Sidecut Radius: 29 m

Effective Edge: 1150 mm

Mount Point From Tail: 795 mm

Tip Height: 54 mm

Tail Height: 23 mm

Camber: Rocker

Dimensions: 120-104-112 mm

Weight: 1720 gr

Sidecut Radius: 29 m

Effective Edge: 1220 mm

Mount Point From Tail: 825 mm

Tip Height: 54 mm

Tail Height: 23 mm

Camber: Rocker

Dimensions: 121-104-112 mm

Weight: 1827 gr

Sidecut Radius: 29 m

Effective Edge: 1290 mm

Mount Point From Tail: 860 mm

Tip Height: 54 mm

Tail Height: 23 mm

Camber: Rocker

Dimensions: 121-104-113 mm

Weight: 1891 gr

Sidecut Radius: 29 m

Effective Edge: 1350 mm

Mount Point From Tail: 890 mm

Tip Height: 54 mm

Tail Height: 23 mm

Camber: Rocker